FOOD HYGIENE AND SAFETY - LEVEL 2 COMPLIANT - CERTIFICATION

Updated on 2026

Lesson 8: summary

The HACCP self-control system corresponds to the acronym Hazard analysis and critical control points.

This system allows us to anticipate problems, it is a prevention system, and if problems arise, it also specifies what we should do. Its compliance is REQUIRED by all food companies and its PURPOSE is to obtain safe food for the health of the consumer.

HACCP is specific to each food business.

The STEPS for its correct implementation in the company are: create a HACCP team, describe the product, identify the expected use, develop a flow chart and comply with the principles of HACCP.

We must comply with the PRINCIPLES of HACCP, which are: identify hazards, set preventive measures, critical limits, monitoring system, corrective measures, control system or recording.

REGULATION

Both the training of handlers and the implementation of HACCP are mandatory and are determined by different regulations. These are the most important ones:

RD 202/2000. Set the rules to be followed by food handlers. It was repealed by RD 109/2010, which established that food companies are responsible for the hygiene of their facilities and food products and the implementation of an appropriate control system in accordance with HACCP systems.

Lesson 8: extended

First of all, it is important to know the meaning of HACCP: the acronym HACCP stands for Hazard Analysis and Critical Control Points.

Now that we know what HACCP is, we must know that this system is the one that allows us to identify, evaluate and control all those points that can be dangerous, as well as establish preventive measures to eliminate them and/or reduce them to acceptable levels.

Its compliance is REQUIRED by all food companies and its OBJECTIVE is to obtain safe food for the health of the consumer.

Each HACCP process will be specific to each food company, as it will be different depending on the food products to be handled or processed in the establishment.

The success or failure of HACCP in food safety depends mainly on the involvement of all those involved in food handling. It is important that everyone is aware of its usefulness and knows what to do at each stage. The previous steps to follow for a correct execution of the system are: to form a HACCP team, to describe the product, to identify the expected use, to develop a flow diagram and to comply with the HACCP principles.

Before starting to elaborate the HACCP process, a few STEPS must be followed for its correct implementation in the business:

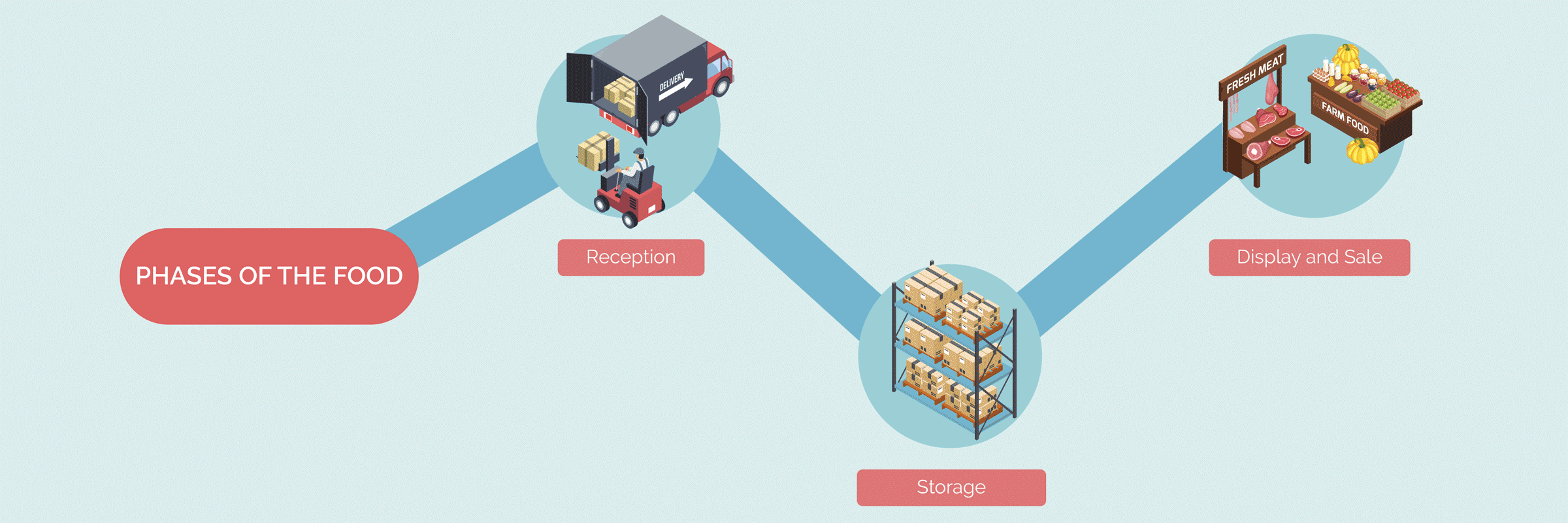

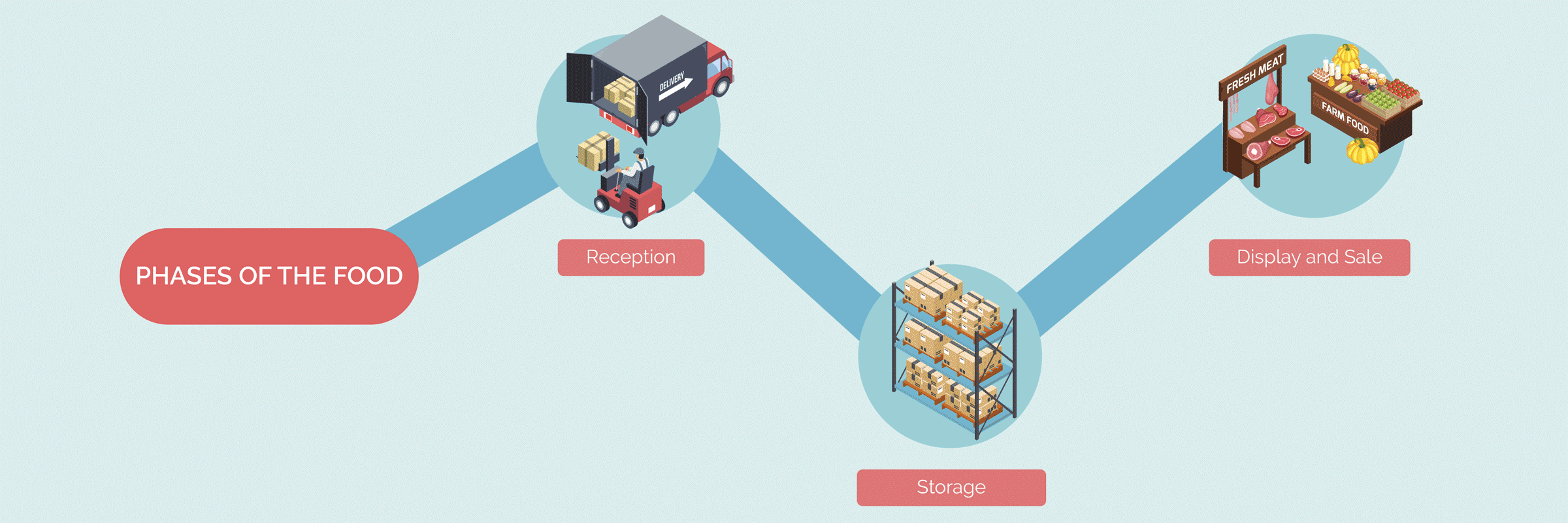

To better understand the HACCP system we are going to assume that we are in an establishment selling products to the consumer, supermarket, hypermarket, and we are going to define the phases through which our food would pass:

Raw materials reception -> Storage -> Exhibition -> Sale.

Complying with the HACCP plan will allow us to obtain safe food and the process will be carried out with fewer errors. In this way, we will also improve the use of the processes and make economic savings. The principles of HACCP in the hospitality industry are to identify hazards, apply preventive measures, establish critical limits, a surveillance system and a control and registration system.

Hazards can occur at every stage of the process. We must know what can happen in order to avoid it as much as possible. This way we would say which are the PCCs (critical control points) in our process.

We must put in place measures that will prevent the emergence of dangers. E.g. in the storage of refrigerated food: always keep it refrigerated (0-5ºC), do not leave open doors in cold rooms for long periods of time, do not exceed the storage capacity...

We must know what is the limit that we consider to be valid and from when this process has become a danger. E.g.: refrigerated food will have a temperature of 0-5ºC (that is the limit), if we have a chamber at 6ºC it will no longer be valid.

Check that the preventive measures are carried out correctly.

Even if we do everything right, there may be a danger, and we must know what to do about it, and how to remove it as soon as possible. E.g. in the frozen food store we see that the temperature is -10ºC, it is not correct, and the food is bad.

Everything that happens, or that we monitor, should be recorded to keep a record of what happens, and taken as proof that the controls have been carried out.

We use 256 bit SSL encryption technology to guarantee the security of our website. You are safe with us.